Industry Leading Automotive Parts CNC Manufacturing Equipment

Japan’s Best Kept Secret

World-class automobile parts manufacturers throughout East Asia depend on HARU CNC equipment to produce their differential cases, axles, driveshafts, gears, and more.

From done-in-one designs to fully-automated lights-out turnkey production lines, HARU Technique Laboratory has the expertise and experience to meet your needs with better precision and speed than anyone else on Earth.

A New Era Begins

After 20 years of manufacturing excellence in Japan, Korea, China, India, and other Asian countries HARU is looking West with Yamashita Machinery.

Proven CNC Performance

Differential Cases Done-in-OneCircumferential Drilling MachinesRear Axle Milling MachinesCentering MachinesFacing MachinesBroaching MachinesCustom Machining Designs

-

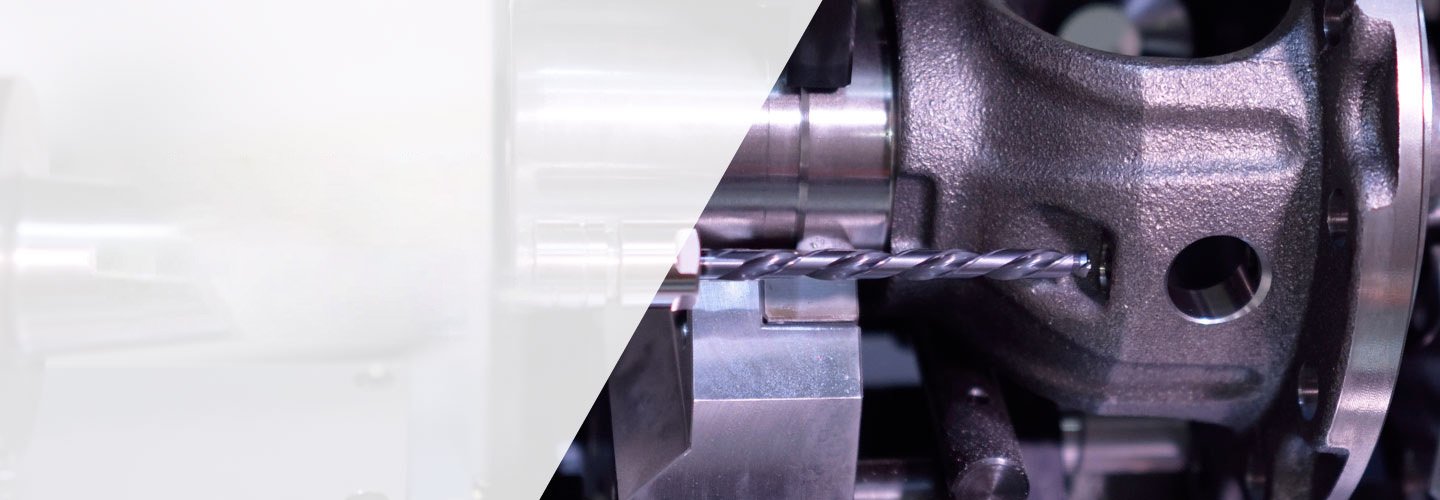

Differential Cases Done-in-One

Multi-machine, single Op production of diff cases leaves you at the mercy of machine downtime and workholding imprecision.

HARU’s unique done-in-one CNC design receives an autoloaded raw part and delivers a perfectly machined, high precision finished diff case every time. Interchangeable workholding enables quick changeover between diff case sizes and configurations.

-

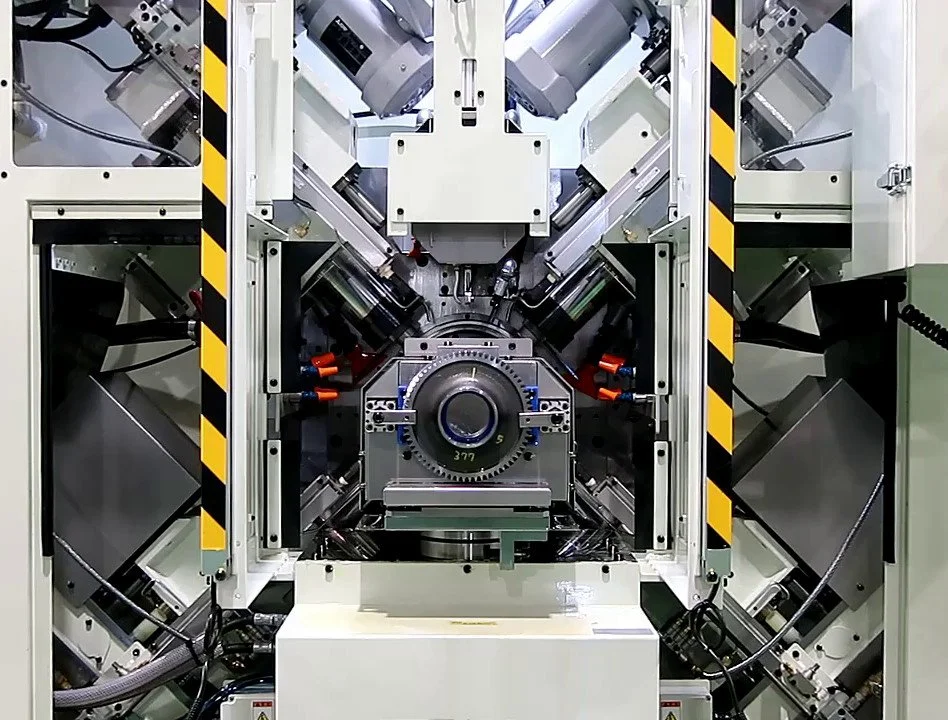

Circumferential Drilling

With four spindles, reversible pallets. gear tooth indexers, 6 axes of motion, and optional autoloaders the HARU Circumferential Drilling platform is superior in every way to using a 3 axis mill and 4th axis rotary add-on.

Contact Yamashita Machinery today and elevate your cylindrical parts drilling with the world’s best equipment.

-

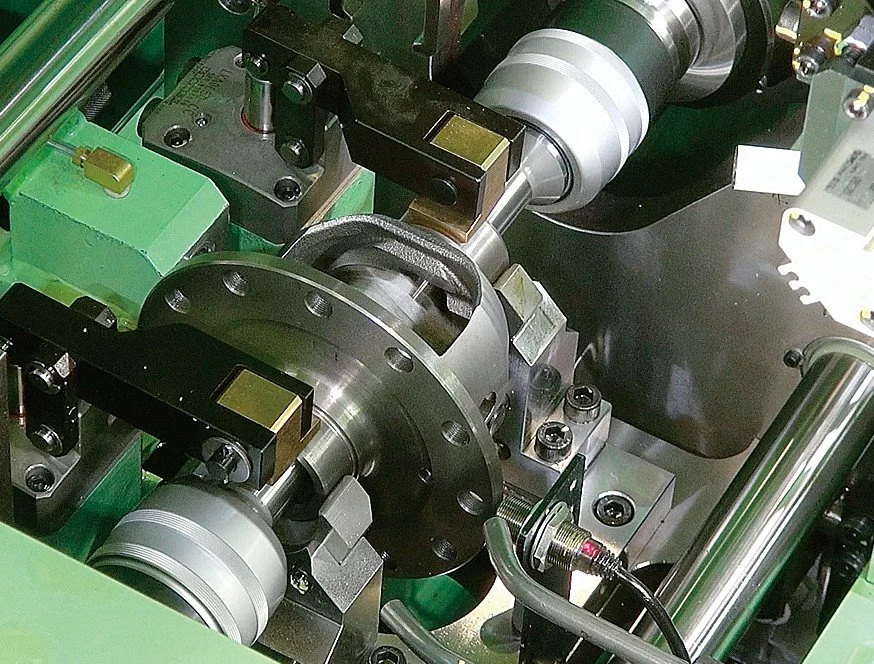

Rear Axle Housing Machining

Don’t waste time piecing together your axles bit by bit. HARU Axle Housing Machining Centers receive your complete axle assembly and machine the lateral faces, saving your plant time and money. Each machine’s workholding is customized to fit your axle assembly, and autoloading is available.